Advanced guide to In-Store Jewellery Cleaning

using the JCR 150R Ion-Stream Commercial

The JCR system is remarkably simple, yet extremely powerful. It has the ability to revolutionise the way display stock jewellery is cleaned and kept clean. Stock can be kept in pristine order with the minimum of effort and cost, and be rapidly cleaned every week to maintain the display.

The system is safe to the operator and to all stones and requires the minimum of staff training

The following is intended to help experienced users maximise the full cleaning potential of this system for cleaning large jewellery collections, shop stock, or retail displays, and assumes that the unit is correctly set up and working.

Table of contents

- Introduction to the JCR Cleaning System

- The JCR 150R Series II and the Retail Jewellery Industry

- An overview of basic principles when using the Ion-Stream Commercial

- Initial cleaning of display Jewellery in detail

- Make sure that the unit is charged

- Previously cleaned stock will need an initial intensive processing

- The Dipping Hook

- Good electrical contact is vital for the process

- Confirmation of good electrical contact

- Removal of oil, dirt, tarnish and previously used cleaning chemicals

- Stubborn remaining stains

- Rinse the surface of the cleaned jewellery or staining will result

- Dry the jewellery with a soft cloth

- Refreshing stock previously cleaned with the JCR System

- Using the JCR in conjunction with an ultrasonic cleaning tank

- Cleaning blackened or patinated surfaces

- Naturally blackened old patinated surfaces

- Forming the blackened new surface quickly in the workshop

- Tarnishing in the showroom is caused by a gas

- Removal of natural tarnish by turning the black compound on the surface back into a gas

- Cleaning chemically blackened patinated surfaces and a note of caution

- The delicate balancing act when cleaning patinated surfaces, and a note about metal ions in the electrolyte solution.

- Technique to remove the effects of the showroom air and handling on chemically blackened piece

Introduction to the JCR Cleaning System

This system is very effective, safe, simple and powerful and will not damage the polished surface of metal or gem stones. Even extremely tarnished and dull surfaces can be cleaned. The candelabrum, below, was cleaned with this system and received no polishing after the process. The JCR Cleaning System removed the heavily tarnished surface on the candelabrum, as seen on the right, and returned it to its original highly polished surface. Relatively short term free air tarnishing does not affect the polished surface of the metal to any great extent, as can be seen in the images below.

The above candelabrum was cleaned using a specially designed machine known as the JCR Ion-Stream Pulse – this uses exactly the same techniques and principles as the Ion-Stream Commercial, but is significantly more powerful and intended for very large items.

The JCR 150R Ion-Stream Commercial and the Retail Jewellery Industry

The Ion-Stream Commercial (JCR 150R) Complete Kit

At a glance - the JCR advantages over traditional cleaning processes

• Stones will not be damaged, including pearl, shell coral, turquoise, malachite, lapis lazuli

• Will remove oil from handling and tarnish at the same time almost instantly

• Will clean matted surfaces

• No loss of metal

• Polished metal will not be damaged

• Sharp metal edges will not be lost in the process

• No need for impregnated polishing cloths

• Can be used together with an Ultrasonic cleaner for initial cleaning, combining the strengths of both systems

• Safe to the operator

• The process is very quick, usually 3 seconds for lightly tarnished pieces, silver or gold.

• Can be used on chemically blackened and patinated surfaces. Please see technique below

* It is possible that artificially added colour could be leached from treated stones but we have not heard of this happening

We have designed the JCR 150R to cater exclusively for the jewellery retail industry.

The JCR 150R is designed to clean relatively small surface areas with light to medium tarnishing. It will also clean very tarnished surfaces but several cycles of the automatic timer are required. The electrolyte is designed to remove tarnish, oil and dirt simultaneously, revealing a super clean reflective surface.

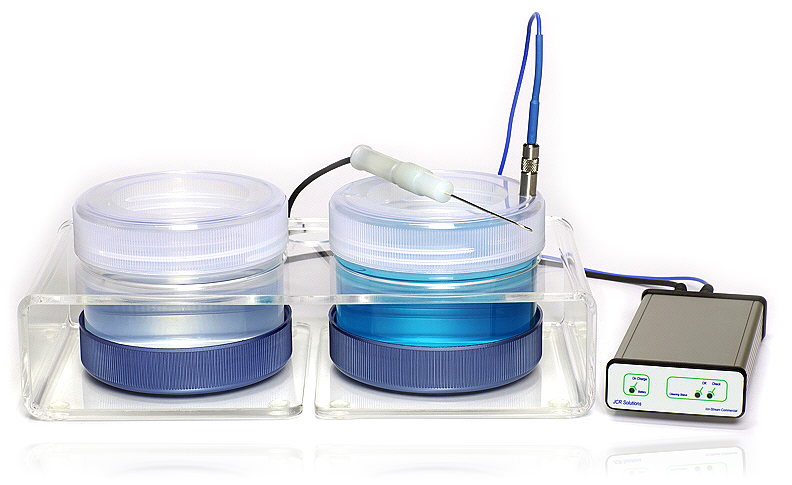

Custom baths and racks for batch cleaning and multiple items

Custom racks and baths can be easily made by the user to suit particular needs. JCR Solutions is happy to supply jigs or custom baths, but this equipment can easily be made in any jeweller’s workshop. Feel free to contact us if you would like advice for a specific application, or would like us to quote on manufacturing a bath to suit your needs.

The images above show some examples of custom baths for batch cleaning multiple items. These were made from heat welding low density polyethylene (LDPE) plastic. Simple custom racks can be made from bending sterling silver wire, and attaching to the black wire with the optional crocodile clip. We recommend using 1.5mm diameter Sterling silver wire which can be purchased from any jewellery making store.

An overview of basic principles - using the Ion-Stream Commercial

The process has been designed to be easy and quick and safe but it is important to follow a few simple rules…

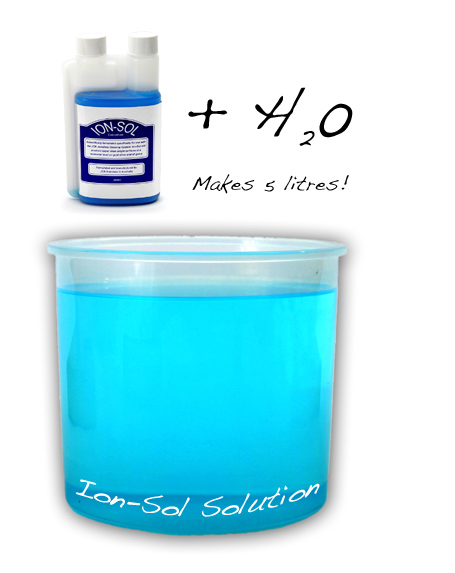

JCR Ion-Sol Concentrate

Ion-Sol is supplied as a concentrate. Before use, it must be diluted with distilled or deionised water at a rate of 250ml per litre of water. Ion-Sol contains a very effective polarised surfactant. It is alkaline and will cause irritation to the eyes and skin. It is possible that some people will be particularly sensitive to the surfactant. Because of this, it is very important that splashes are washed from the skin or eyes. Take care not to breath the aerosol created above the bath when using the unit together with an ultrasonic tank. Take the same sort of precaution that would be taken when using any detergent or other chemicals. We suggest that rubber gloves are worn when cleaning. Keep the electrolyte out of the reach of children. Wash hand after use.

Water and electrolyte quality is very important

- Tap water or untreated water can cause problems. We recommend that only distilled or good quality deionised water is used to dilute the electrolyte concentrate. If it is not used, the cleaning process will not be as efficient as it could be. In the worst case, the surface of the metal may be stained or made less bright by contaminants in the water.

- Fresh electrolyte works best; we recommend that the solution is changed frequently as contaminates from dirty jewellery will accumulate inhibiting efficient cleaning.

Setting up the cleaning bench

Set up a cleaning bench so that the operator can work freely. Wash the bath out before use, rinse it with clean water and wipe it dry with a clean soft cloth.

Connect up a fully charged 150r unit as described in the instruction manual. Pour 250ml of Ion-Sol concentrate in the bottom of the supplied 1 litre bath, and fill with distilled or deionised water, then stir until dissolved. Attach the dipping hook and the stainless steel electrode to the JCR unit.

The rinsing bath

Place a rinsing bath to the right of the electrolyte bath. This should be as large as is possible so that the water will not need changing as frequently as it would with a smaller container. Good quality treated town water can be used for rinsing the jewellery. If the water is not good quality or if it contains sulphur, as is the case with some bore water, the surface of the metal may become stained after cleaning. If the quality of water is not good then it would be advisable to use deionised water. Rain water is a good alternative.

Using an optional second rinsing bath

The 150R jewellery cleaning station shown with the optional rinse bath and counter-top tray

A second rinsing bath can be used if required, but is not essential. This bath should contain clean rinsing water as before, but with the addition of a teaspoon of alcohol (methylated spirit) to 1 litre of water. The alcohol will reduce the surface tension of the water, preventing the water beading on the surface of the metal. This helps to overcome drying marks on the jewellery. Another advantage of the second bath is that it will ensure all residual electrolyte is removed from the item, leaving the surface absolutely clean and bright.

Change the water in rinsing baths frequently

After many items have been cleaned and rinsed, the rinsing bath will loose its effectiveness. The concentration of chemicals from the electrolyte bath will start to build up in the water as small amounts will be carried over with each piece of jewellery that is rinsed. It is important that the rinse water is changed frequently as under some conditions premature tarnishing of the cleaned jewellery will result.

Cleaning the jewellery

We suggest that jewellery to be cleaned is carefully placed to the left of the cleaning bath so that the cleaning process moves from left to right.

Each piece of jewellery is processed in the JCR bath as above. Remove it from the dipping hook, inspect it and if slight staining remains, gently brush it with a soft wash out brush. If the surface is still tarnished then repeat the dipping process. Rinse the item in the rinsing bath and pat it dry with a soft lint free cloth.

Initial cleaning of display Jewellery in detail

It is important to note that even a heavily tarnished dull piece of display jewellery still has the original polished surface it was given by the jeweller.

Make sure that the unit is charged

An overnight (12-14 hour) charge normally lasts for at least 200 cleaning cycles. If the blue check light illuminates when the dipping hook is immersed into the solution the battery needs recharging.

Previously cleaned stock will need an initial intensive processing

If stock jewellery has previously been cleaned using chemical dips, impregnated polishing cloths or it just looks tarnished and very tired, an initial cleaning will be required. This is a little more labour intensive than will be the case in the future. Future cleanings, if conducted regularly, will only take a few seconds per item.

The Dipping Hook

Select a piece for cleaning and place it on the silver dipping hook. Most pieces can be hooked on, but in some cases a jig must be made to accommodate this. It is usually in the form of thin silver wire that can be threaded through the item. This is looped onto the dipping hook. Once made, the jig can be kept with the cleaning kit ready for the next time.

Good electrical contact is vital for the process

This can sometimes be inhibited by oil from handling and other accumulations of dirt and tarnish. If possible, select a relatively clean area of metal and loop it onto the dipping hook at this point. With the item on the dipping hook, lower it into the electrolyte and the unit will switch on automatically.

Confirmation of good electrical contact

The quality of connection can be confirmed by observing that the blue OK light on the JCR unit has lit up. This should remain on whilst the item is in the solution. If the light does not illuminate, or it flickers and the blue check light illuminates, remove the item from the solution and re-immerse. If the blue check light continues to illuminate the unit may need recharging.

Removal of oil, dirt, tarnish and previously used cleaning chemicals

Contact will be made as the oil or dirt will be displaced by the electrolyte. Leave the item in the solution for up to one cycle, which is approx 40 seconds. The blue OK light will switch off automatically at this point. Take the hook and item out of the solution. Remove the jewellery from the hook, and brush the piece carefully with the wash-out brush which is supplied with the kit. This will remove all traces of tarnish and previous chemicals, leaving the surface bright and clean. Heavily tarnished surfaces may need more “dippings” to achieve a clean surface.

Remaining stains

Very rarely, stains will remain and these can be removed using a paste of JCR Brushing Medium on the wash-out brush and gently brushing the surface with it. For more information refer to the article Using Baking Soda (Sodium Bicarbonate) to clean jewellery

Rinse the surface of the cleaned jewellery or staining will result

Once clean of tarnish and stains, thoroughly rinse the item in the rinse bath. If this is not done staining may result on the surface. A third rinse bath can be used but is not essential. This bath would contain clean rinsing water with the addition of a teaspoon of alcohol (Methylated Spirit) per 1 litre of clean treated water. Alcohol will reduce the surface tension of the water preventing it beading on the surface. This helps to overcome drying marks on the surface of the jewellery. See a short video of the alcohol rinse technique.

Dry the jewellery with a soft cloth

Once the item is rinsed clean, pat it dry with a soft cloth. There is no need to use an impregnated polishing cloth for reasons outlined at the beginning of this section.

We recommend that impregnated cloths are not used with the JCR system as they will leave traces of abrasive, and in some cases, chemicals on the surface of the jewellery.

In use, these cloths become oily from handling and will pick up abrasive particles. When rubbed on the surface of the metal it is possible that they will deposit a smear of oil and scratch the surface of the metal and stones.

Refreshing stock previously cleaned with the JCR System

Dip the item in the electrolyte for 2 or 3 seconds, rinse and dry.

When the time comes to refresh tired-looking stock, follow the previous instructions but this time dip the item in the electrolyte for 2 or 3 seconds. Rinse and dry as described above. If the item is very tarnished or greasy from handling, it may need a little more time in the solution but 2 or 3 seconds is a good starting point. Rinse as described above.

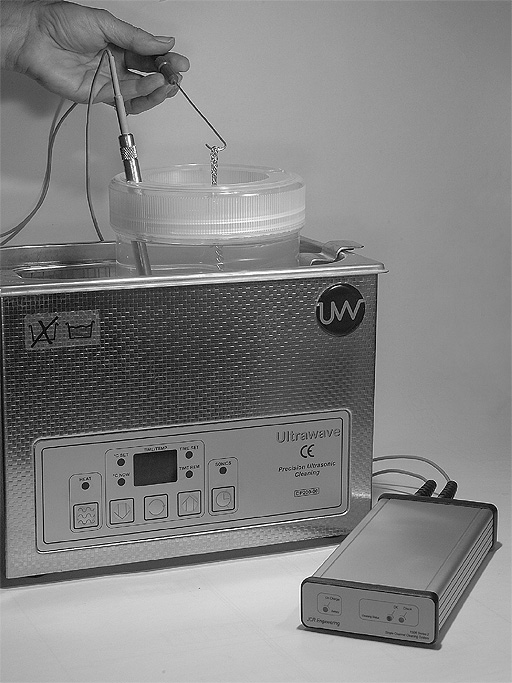

Using the JCR in conjunction with an ultrasonic cleaning tank for initial cleaning of heavily tarnished or particularly dirty jewellery.

Dip the item in the electrolyte for 2 or 3 seconds, rinse and dry.

When the time comes to refresh tired-looking stock, follow the previous instructions but this time dip the item in the electrolyte for 2 or 3 seconds. Rinse and dry as described above. If the item is very tarnished or greasy from handling, it may need a little more time in the solution but 2 or 3 seconds is a good starting point. Rinse as described above.

Using both systems together can produce astonishingly quick results, but care must be taken not to clean jewellery which is set with delicate stones or enamel in the ultrasonic tank. The ultrasonic pressure waves are very good at removing loose particulate matter but will damage some stones or enamel.

Method

Place a full JCR electrolyte bath into the tray of the ultrasonic tank, then fill the ultrasonic as normal with plain water to its recommended level. Connect the JCR as usual and place the item to be cleaned on the dipping hook. Switch the Ultrasonic on, and immerse the item into the JCR electrolyte, which will automatically initiate the JCR cleaning cycle.

The automatic timer will switch the JCR off after approximately 40 seconds. The blue OK light will go out. Remove the dipping hook with the item attached and inspect the quality of finish. If it is still tarnished or dirty, lower the dipping hook back into the electrolyte and initiate a new cycle. Once clean, thoroughly rinse in clean water. If a second rinse bath is being used, dip the clean item into the water, remove and pat dry with a soft cloth.

Using an ultrasonic cleaner with the JCR is particularly good for cleaning chains. Extreme caution must be exercised as it is possible to damage delicate stones and enamels.

Cleaning blackened or patinated surfaces

A little background on tarnish and patination of the silver surface

Naturally blackened old patinated surfaces

The purpose of applying the black surface onto silver is to simulate the effects age. In the natural process, and as the item ages, the silver naturally tarnishes and the high spots are rubbed clean of the tarnish leaving them bright and white. The contrast gives a pleasing result but it takes a long time.

Forming the blackened new surface quickly in the workshop

The aging process can be reproduced on new pieces. It is done by using very concentrated chemical solutions, mostly acidic, which turn the surface black instantly. The chemicals are usually tellurium sulphide, copper sulphide, or what is known in the trade as liver of sulphur. Sulphur has a great affinity for silver. Once in contact with the silver there is a chemical reaction on the surface leaving a black stain. It is a chemical compound and cannot be removed using an ultrasonic cleaning process.

Tarnishing in the showroom is caused by a gas

Sulphur in the form of hydrogen sulphide gas is what normally tarnishes silver in the showroom, but it would take a long time to become as black as the stain on chemically patinated surfaces. This reaction is called oxidation. Learn more about how tarnish is caused, and techniques to reduce it.

Removal of natural tarnish by turning the black compound on the surface back into a gas

Very reactive chemical dip cleaners, or energy supplied by electrolysis (The JCR System) are needed to change the chemical on the surface back into a gas. The gas is called hydrogen sulphide and smells like bad eggs. This process is called reduction.

Cleaning chemically blackened patinated surfaces and a note of caution

When processed by the JCR system the black chemical compound on the surface will undergo a reduction process. It will slowly change the black compound on the surface into a gas called hydrogen sulphide. This can be smelt above the surface of the cleaning bath as “bad eggs”. If it is processed long enough, the entire compound on the surface would be converted into a smelly gas and a loosely attached lattice of black stain. If desired, this lattice could be removed mechanically by brushing or rubbing with a cloth. It could also be removed placing the item in an ultrasonic tank.

The complete removal of the black stain is not wanted when cleaning a blackened surface

There is a delicate balancing act to be undertaken, which is fortunately, very easy to perform.

The delicate balancing act when cleaning patinated surfaces, and a note about metal ions in the electrolyte solution.

When chemically patinated pieces are processed by the JCR system, metal ions will be released from the blackening chemicals into the electrolyte solution. If the concentration is allowed to build up, the metal ions will plate out onto the surface of the item being cleaned. It will be seen as a yellow to black stain. This is not a problem on the dark areas but is undesirable on the bright polished areas. Fortunately, the silver dipping hook will act as an indicator, as its normally white surface will become coloured. However, this effect is not common if the instructions are followed, and is an extreme case of what can happen. In practice, it is not a problem if the process is understood. The effects, if experienced, can be easily remedied by rubbing the high spots with a soft cloth charged with a little jewellers rouge.

This process does require a skill to be learned by the operator, but will pay dividends in time saved and will retain highly polished surfaces. Highly polished surfaces cannot be damaged by the JCR system. Polishing cloths will pick up oil and large abrasive particles in use and are not recommended for use with this system. Their use can result in scratched smeary surfaces.

The effects of the showroom air and handling on chemically blackened pieces

The bright polished surfaces of patinated pieces are subject to the normal tarnishing process, and become tired looking if handled frequently. They can be brought back to showroom condition safely and almost instantly by following the technique below

The technique

- Place the item on the dipping hook and make sure that the silver hook is in good contact with the jewellery. This will be confirmed as the blue light on the JCR will illuminate and remain on constantly whilst the item is in the solution.

- Dip the item into the solution for a count of two seconds and at the same time check to see that the blue OK light is on. Remove the piece from the solution. Rinse in good quality clean water and pat dry but do not rub or brush the black areas whist the item is wet.

- Should the item not be bright enough, repeat the above procedure, but be aware of how the process works. The JCR will remove the black compound if exposed to the process for too long.

- Repeat cleanings can be done in exactly the same way when necessary.

Note: There will be a build up of contaminants in the electrolyte solution, as described above, and this is unavoidable. It is vitally important to keep the solution fresh. Keep the dipping hook clean as it will show a mild discolouration if there is a problem with the solution. Should the bright surface of the jewellery or dipping hook become coloured it can be simply wiped with a soft cloth charged with a little fine jewellers rouge. The electrolyte solution will need to be changed much more frequently than when cleaning untreated surfaces. Experience of the process will provide a guide as to when the solution is replaced.