Professional gold and silver Jewellery Cleaners

Established in 2003, JCR Solutions design and manufacture safe, non-toxic and innovative in-store jewellery cleaning products specifically designed to help retailer’s keep their stock clean with minimum time and effort. All our products are designed and manufactured by us in Australia. We combine modern electronics and classical chemistry to produce a controlled and repeatable ionic based cleaning system that gently removes tarnish from silver and gold as well as removing grease and grime from handling. It is fast, safe on all natural stones and safe on all precious metals.

A fast and efficient jewellery cleaning system designed to effortlessly maintain a vibrant retail display – and present your jewellery in the most attractive way possible….

An enormous amount of research, time and resources are routinely put into the design and layout of retail displays to maximise sales. Unfortunately this is far too frequently let down by the less than optimal condition of the jewellery on display. From the moment the item leaves the jeweller’s workshop it becomes progressively more and more tarnished. This is a particular problem with silver and low carat gold items.

The inevitable tarnish and oxidation of polished gold and silver jewellery in the showroom is caused by sulphur in the form of hydrogen sulphide gas combining with the silver to form silver sulphide (the brownish tarnish on silver). The natural tarnishing process is further accelerated by frequent customer handling, and by “outgassing” from the plastics used in the materials, construction and finishing of retail display cabinets, and even the jewellery packaging. The outgassing from the retail cabinets is often made even worse by the heat from the lighting. Find out more about the tarnishing process and how to minimise it…

An extremely gentle cleaning system that reverses the natural tarnishing process. Safe on all natural stones including pearl, amber, coral, shell, lapis lazuli, opal, emerald, haematite & diamonds, does not burn or erode precious metals, effortlessly clean complex shapes and textures.

A very different approach to regular jewellery cleaning practices

For retail display cleaning, the most common approaches tend to centre around the use of abrasive polishing cloths, chemical dip cleaners, and most commonly, ultrasonic cleaners. Instead of using abrasion, reactive chemicals or high frequency sonic pressure waves, the JCR system uses a slightly alkaline, non-toxic and non-hazardous ionic solution called Ion-Sol.

JCR Ion-Sol is formulated and exclusively manufactured by us. learn more about Ion-Sol…

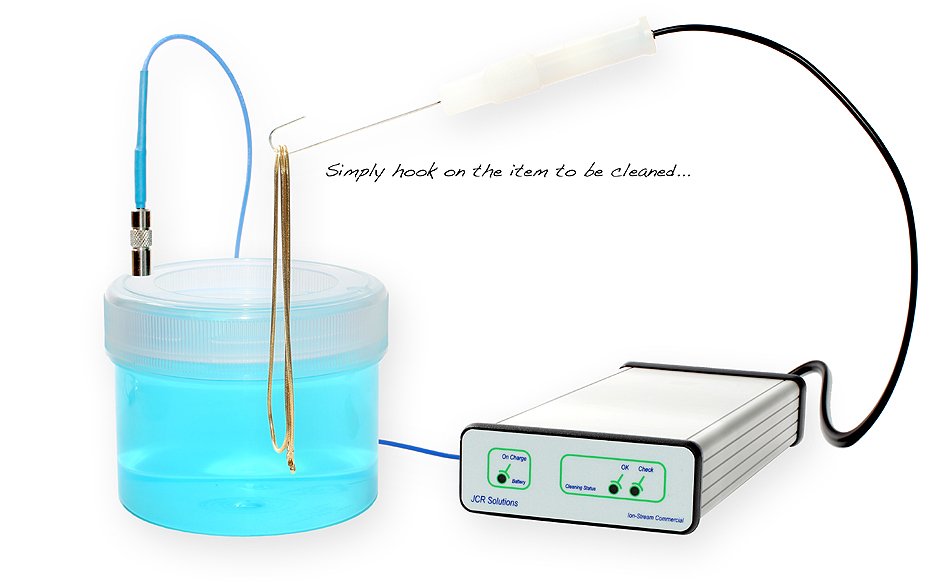

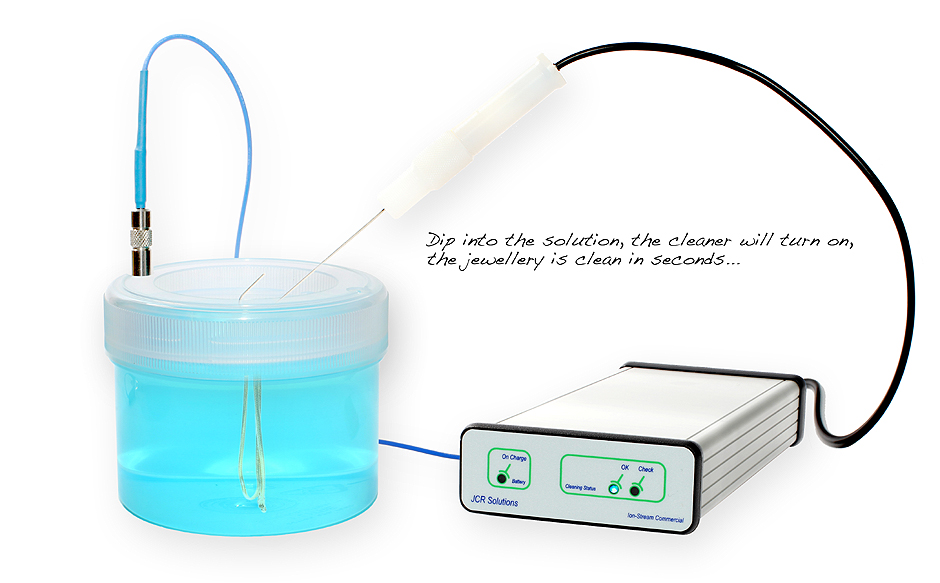

To clean jewellery, a small and carefully controlled ultra-low voltage electrical current is passed through the electrolyte (Ion-Sol), creating a gentle and repeatable electrolytic reaction. The flow of current causes the formation of hydrogen ions, and small bubbles of hydrogen to form on the surface of the item being cleaned. The hydrogen bubbles help scrub the surface by freeing surface particles of dirt, and also help the detergent in the solution to emulsify with and remove grease and oil. More importantly, the newly formed hydrogen ions combine with the silver sulphide (the tarnish), which converts it back into hydrogen sulphide gas which simply bubbles out of the solution. This has precise symmetry with the original natural tarnishing process, reverting the precious metal surface back into it’s original pre-tarnished condition. Because the cleaning process is performed at room temperature and uses a non-acidic solution It is safe on all natural stones and all precious metals.

The gentle conversion and removal of tarnish gives ionic cleaning a massive advantage over ultrasonic cleaning.