Getting started with a JCR 150R Ion-Stream Commercial Jewellery Cleaner

Short video showing how to connect up and get started with an Ion-Stream Commercial

The following is taken from the user manual, and intended to help users set up and get started with an Ion-Stream Commercial. For more advanced information, please refer to the Jewellery Cleaning Guide for Retailers, and if needed, refer to the advanced troubleshooting guide to solve any issues you may be encountering.

This document can be downloaded for personal offline use as a PDF eBook in English or in Chinese by clicking on the icons below;

Table of contents

- Introduction to the JCR Ion-Stream Commercial

- Charging the internal battery

- The leads and electrodes

- Mixing the electrolyte (Ion-Sol)

- Cleaning hints and tips

- Reading the front panel LED indicators

- Cleaning gold and silver jewellery

- Cleaning copper, brass and stainless steel

- Using in conjunction with an ultrasonic cleaner

- General Troubleshooting

Introduction to the JCR Cleaning System

The Ion-Stream Commercial (150R) is a smart and versatile product designed for routine cleaning of jewellery for display and specifically to clean jewellery set with delicate or chemically reactive stones. It is made to be versatile and simple in use. Its principle use is the quick and safe removal of tarnish from the surface of gold and silver. It can also be used to clean stainless steel and other metals. The 150R can be used with great advantage in conjunction with an ultrasonic cleaner provided the item is not set with delicate stones. To remove tarnish, oxidisation and oil or grease residues from any conductive surface using the electrochemical process of electrolysis.

In use the item is placed in a non-hazardous electrolyte which has a pH of approx 9.1. This means that it is slightly alkaline and can’t damage chemically active gems like opal, ironstone, lapis lazuli, turquoise, coral, pearls etc.

A carefully measured and regulated current is applied to the surface of the item being cleaned irrespective, of the distance between the electrodes. In practice millions of tiny hydrogen bubbles are formed on the conductive surface of the jewellery connected to the cleaning electrode. These bubbles dislodge and then mix oily molecules with the electrolyte, which contains an effective degreaser. Weak molecular bonds which hold the dirt in place are released by the action of the current. The removal of tarnish from silver is almost immediate taking approximately 2 – 5 seconds. Tarnish from gold takes slightly longer at around 5 seconds. This form of cleaning also removes oily and greasy deposits off the surface of gems and diamonds, leaving them sparkling.

The 150R contains an internal timer. This timer automatically starts when the electrodes are placed in the electrolyte. At the end of the cycle the 150R returns to standby mode. The clean cycle can be interrupted at any time by removing one or more electrodes. The timer immediately resets placing the unit in standby mode, ready for the next cleaning cycle.

Charging the internal battery

The 150R contains an internal high quality Ni-MH rechargeable battery pack and battery management circuit. It has been designed to charge the battery at the optimum rate in order to maximise serviceable battery life.

To charge the battery pack plug the charger into the Power socket at the rear of the unit. Only use the supplied charger, and never exceed a continual charge time in excess of 14 hours.

In practice, regardless of the state of charge of the battery, it is quite acceptable to perform an overnight charge before each day of service.

The blue charge light on the front panel will glow to indicate that charging is in progress.

The rear panel of the Ion-Stream Commercial

To protect the operator from potential electrical hazards the functionality of the unit is disabled during charging – the charge plug must be unplugged from the back of the 150R before it will operate. Charging may be interrupted and resumed at any time by simply removing the charge jack from the rear of the unit. This ensures the user is isolated from line voltages at all times.

For safety reasons the internal battery is distributed in a discharged state. We recommend that it is given an overnight charge before it is put into service (an overnight charge is defined as a 10 – 14 hours). From this point forward it is quite acceptable to “top-up” the battery pack as required.

After a full overnight charge the battery will typically run for about 150 minutes of continuous cleaning. When used to clean retail stock, a typical clean will take under 8 seconds. A full charge can clean well over 500 items.

When the battery is too discharged to clean, the blue Check indicator will consistently glow. At this point it is advisable to give the battery a complete overnight charge.

The Electrodes and Leads

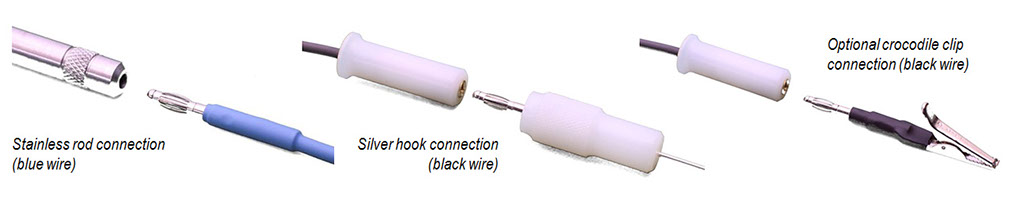

You have been supplied with a set of premium quality leads and electrodes. The leads are made from high quality durable, chemical resistant and flexible silicon insulated wires. There are two interchangeable cleaning electrodes – a silver hook, and an optional crocodile clip. These can be selected according to application. The electrodes simply plug onto the electrode lead using industry standard 4mm plugs. All parts are available from JCR Solutions as replacements or spares.

Black lead (for hook or crocodile clip)

Sterling Silver Hook electrode

Optional Crocodile clip

Blue lead (for stainless steel rod)

Rod Electrode (10mm machined stainless steel rod with 4mm socket)

The silver hook electrode is ideally suited to most applications. For gold or silver jewellery cleaning the silver hook should be used. The optional clip is provided to enable the user to attach their own custom made silver electrodes. It is sometimes useful to do this in order to clean an awkward or unusual shaped piece of jewellery. The clip simply provides a convenient method of connecting to this electrode. For best results avoid submersing the crocodile clip in the electrolyte – under some conditions it is possible to contaminate the solution, potentially staining the item being cleaned.

The electrode lead utilises standard 4mm plugs and sockets which simply push into place. For the longest possible life apply a small amount of silicon or petroleum grease to the contacts, and try to avoid straining or bending the wires too sharply. They are available as spare parts if required.

Plug the electrode leads into the electrode sockets on the rear of the unit. Ensure the plugs are pushed firmly home and twisted into the bayonet sockets. The black wire plugs into the socket labelled “black”, and the blue wire plugs into the blue socket.

If longer leads or custom leads are required please contact JCR Solutions.

Rear view of unit showing the blue and black electrode lead connections

Mixing the Ion-Sol Electrolyte

For most applications it is favourable to mix 1 litre of electrolyte. This will last for many cleaning cycles and have sufficient volume to clean bulky items such as larger chains or watches.

For best results, when not in use, store the electrolyte in an air tight container to avoid contamination and evaporation.

Dilute the Ion-Sol concentrate at the rate of 50mL per 1L of deionised or distilled water. Measure the water volume carefully as the concentration of the electrolyte is important In order to maximise the effectiveness. Put the lid on the container and shake thoroughly to mix the contents. The electrolyte is now ready for use. For best results use the electrolyte at room temperature.

The Ion-Sol safety datasheets (SDS) can be downloaded and printed for various regions from the links below:

CAUTION!

Through use the electrolyte will gradually become increasingly contaminated with various metal salts, grime and general dirt. Please ensure the container is appropriately stored and labelled. Wash hands after use. Clean up any spills immediately. Observe all precautions reserved for using chemicals. Keep out of reach of children.

Tips when cleaning with the 150R Ion-Stream Commercial

- Tap water or untreated water can cause problems. We recommend that only distilled or deionised water is used to dilute the Ion-Sol electrolyte concentrate. If it is not used, the cleaning process will not be as efficient as it could be. In the worst case, the surface of the metal may be stained or made less bright by contaminants in the water.

- Fresh Ion-Sol electrolyte always works best; we recommend that the solution is changed frequently as contaminates from dirty jewellery will accumulate inhibiting efficient cleaning.

- The electrolyte should be used at room temperature. Some stones such as opal are very vulnerable to sharp changes in temperature and may crack due to thermal shock.

- When cleaning silver or gold do not allow copper, brass or steel to come into contact with the electrolyte as under some conditions black staining of jewellery may occur. For best results only use the silver hook electrode for gold or silver jewellery, the silver hook also serves as a useful contamination indicator – it should always remain clean and bright.

- Jewellery with triplets or doublets should only be cleaned if absolutely necessary, as there is a very high risk that the cemented layers can become detached. We have done extensive tests on the effects using the Ionic 150R on pearls, solid opals, emeralds, ironstone, coral and other chemically active gems and have found it to be safe.

- The customer should assure themselves of the suitability of this cleaner for their jewellery as no responsibility for damage will be accepted by us. Should the customer wish to see the cleaner used on a particular stone of concern please contact us for a risk free demonstration.

- If cleaning jewellery containing opal, emerald and or other delicate gems do not use in conjunction with an ultrasonic cleaner to assist in the removal of grime. In this case a soft bristle brush should be used instead to dislodge particles of dirt or grime.

- The item being cleaned should be in contact with the silver electrode at all times during cleaning. If the item being cleaned inadvertently falls off the hook electrode during cleaning, immediately remove the electrode from the electrolyte to stop the current flow. With heavily used electrolyte, under these conditions it is possible to discolour the item being cleaned. Stopping the current flow by removing one or more electrodes from the electrolyte will prevent this from happening.

The 150R front panel showing the 3 indicators

The Ion-Stream Commercial has 3 blue LED indicators: OK, Check and Charge.

The cleaning cycle is automatically controlled. The OK indicator will be illuminated during cleaning if all electrical requirements are met. If the OK indicator is replaced with the Check indicator then cleaning should be terminated, and the troubleshooting table at the back of this manual should be consulted. In most cases the Check light will be caused by a flat battery or dirty electrode contacts.

Cleaning silver and gold jewellery

- After charging the unit, unplug the charger from the back, fill the cleaning bath with the prepared Ion-Sol and attach both electrodes to the leads. Immerse the stainless steel electrode into the solution. The supplied bath has a hole in the anti-spill lid to support the electrode. Plug the electrode leads into the back of the unit.

- Hook a single item of jewellery onto the silver electrode and simply immerse into the solution. If all is well the OK light will illuminate indicating the cleaning cycle is in progress. During the cycle it is good practice to slowly rotate the jewellery so all surfaces face the stainless steel electrode. Notice the gentle bubbling action. Initially there will be fewer bubbles because the surface of the metal is partially insulated by the grease, oil and dirt. As the metal becomes cleaner there will be more bubbles due to higher conduction levels. Depending on the level of tarnish or grease on the item, the cleaning time can be as short as a few seconds.

- If the jewellery is very dirty or oily, it is advisable to remove it from the electrode, and lightly brush it to remove the now loosened dirt. Hook it back onto the electrode and perform another cycle if necessary. More cycles can be performed as necessary.

- Rinse thoroughly in distilled or de-ionized water and pat dry with a soft lint free tissue. If finished replace the lid on the electrolyte to avoid contamination or evaporation. The solution can be used many times but will need replacing when it becomes dirty or less effective. As with all chemicals care should be taken to ensure that they do not come into contact with food or young children. Normal precautions apply in regards to the use of chemicals.

Cleaning copper, brass and stainless steel

The 150R is also a fantastic cleaner for copper and stainless steel. It is however important that you follow this fundamental rule:

Avoid cleaning gold or silver in an electrolyte that has previously been used to clean copper or brass.

This can contaminate the electrolyte potentially staining the jewellery surface.

(Gold silver and gems can be safely used in the same electrolyte)

Using the 150R in conjunction with an ultrasonic cleaner

The 150R can be used to enhance the effectiveness of any ultrasonic cleaner.

The 150R cleaning bath can simply be placed inside the ultrasonic bath. The ultrasonic pressure waves are able to pass through the plastic container. This method avoids mechanical and electrical coupling between the bath and the electrodes. Mechanical coupling can cause abrasion and pitting to the bath through metal to metal vibrational contact.

In practice, the ultrasonic cleaner can be turned on, and the electrolytic cleaning can be performed simultaneously. This combines the strengths of both cleaning systems.

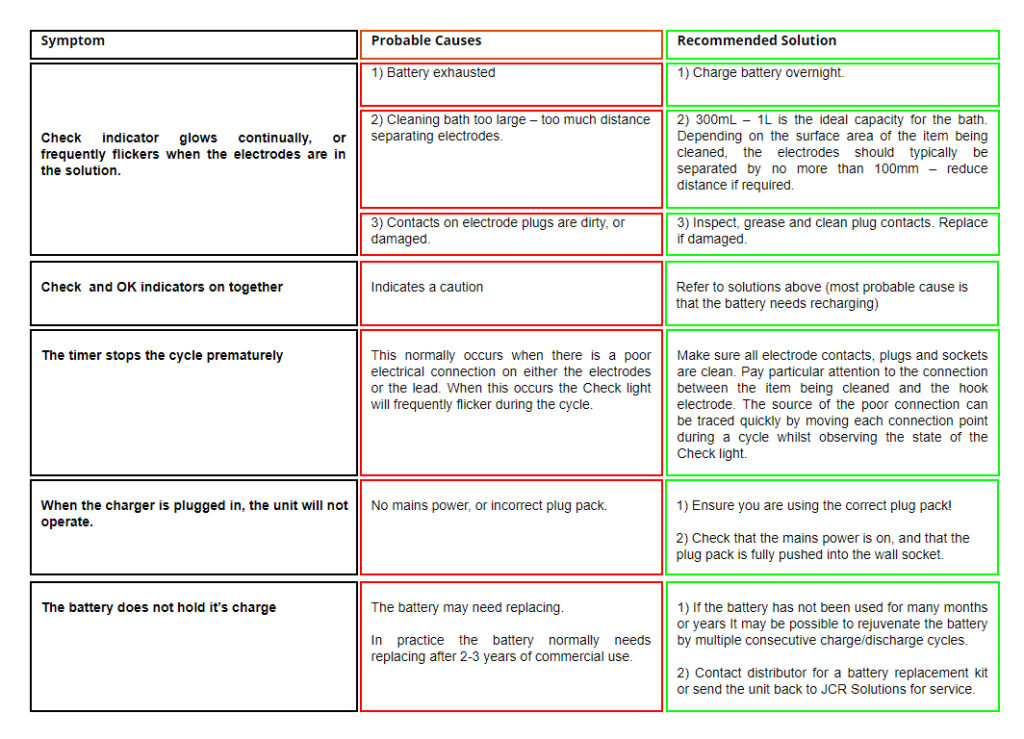

Troubleshooting

In the unfortunate circumstance that trouble is encountered please refer to the following table for help.